No products in the cart.

What to Do if Your Sewing Machine Gets Wet

With the recent flooding in the Great South East, we have received a few emails asking us “How can I fix my sewing machine (or overlocker) after it has been exposed to water?”

Many sewists believe that family, pets, and sewing machines are the first things they would grab in an emergency. Our thoughts are with everyone who is dealing with rising floodwaters , so for the benefit of everyone who has had water on or in their machine from a leaky roof or a rising flood, we have compiled a list of steps that will increase your chances of returning to sewing as soon as possible.

First and foremost, DO NOT TURN ON THE SEWING MACHINE.

This is for your safety and the safety of the electrical components in your machine. When water gets into the electronic circuitry it can short-circuit your boards, which can create a bigger issue! It is important to know that restoring your machine to its former glory will take several days.

If you are in doubt at any time, please give us a call or bring your machine in to us and we will ensure that your machine is safe to use.

So without further ado, the follow are the steps that you need to fix your sewing machine when it gets wet:

What you will need if your sewing machine get wet:

- Paper Towels

- Clear Pharmaceutical Oil (Preferably Spray On / Aerosol Pharmaceutical Oil)

- Hair Dryer / Fan(s)

- Towels

- Tweezers

- Screwdrivers

- If your sewing machine case / frame is metal, Silicone Spray (if available)

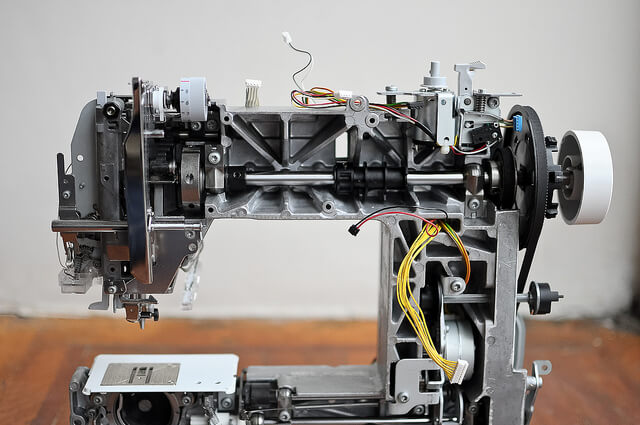

Step 1 - Remove your covers

Water by its very nature will work its way into every nook of your machine. Our first step in evicting this unwelcome addition to our sewing machine is to remove the covers. Depending on the model, you may be able to easily remove either the top, bottom, or both covers. This will expose the inner workings of your machine. With a Screwdriver remove the screws holding the covers in place and then wipe the exterior and interior of the covers.

Step 2 - Remove your Needle Plate, Bobbin Case, and Needles

After removing the covers, remove the needle plate and bobbin case (if a sewing machine) from your machine. Then unscrew your needles and dispose of them.

Step 3 - Remove as much water and moisture as possible

With the covers removed, carefully pack the paper towels into the machine to pull as much water and moisture from the gears and components. You will find that it is easiest to use tweezers to move (and remove) the paper towels in your machine. After you remove the paper towels, turn the handwheel half a revolution and repeat the process. Depending on the extent of the water exposure, you may need to repeat this step multiple times.

Step 4 - Grab a hairdryer or fan

After a hairdryer or fan and blow-dry the machine for 10 to 30 minutes, ensuring that all the internal gearing is exposed to the air. As you blowdry the machine turn the handwheel so that any water hidden between gears will be evaporated.

If you have an electronic machine, apply indirect heat to the circuit boards. Water can get under the small microchips and cause short-circuits, rust, and premature component failure if left. This moisture can take a while to remove and we recommend after applying the indirect heat, running a fan on the open machine for several days after.

If you have difficulty removing the water or are concerned about your electronic components, bring your machine in and we have specialised equipment to remove moisture for the circuits.

Step 5 - Coat all moving parts with Oil

Once you have removed as much water as possible, you will need to add a fresh coat of oil to all moving parts. Place the machine on several paper towels (or a towel) to prevent your countertop from being coated in the excess oil. As you turn the handwheel you will notice the moving piece throughout your machine. Place a drop of oil on each moving piece (and any metal items, like the upper and lower shafts). If you have a Spray Oil (like Inox), this will make this step easier. As you are oiling, continue to turn the handwheel, as it will work the oil into the gears and bearings. This step will take some time as sewing machines and overlockers have a lot of moving pieces.

Step 6 - Coat the external metal in Silicone Spray

Silicone Spray adds a protective barrier on your machine which will reduce the chance that surface rust will appear. Simply spray the exterior of the machine, in addition to anywhere that has not been oiled (with the exception of the motor) and with a paper towel, wipe away the excess.

Step 7 - Wait

This is counter-intuitively the hardest step. If your sewing machine has had any water in any of the electrical components, it is important to not turn the machine on for a minimum of 3 to 5 days. During this time, periodically turn your handwheel and ensure that the machine is not getting tight / seizing. If it is getting hard to turn, repeat the oiling step.

Step 8 - Reassemble and Check

After the waiting period, you can reassemble your machine. Once reassembled, you can plug it in and start testing it. We recommend running the machine without thread for 5 minutes. This will ensure that the oil has worked its way into the gears and bearing. If it is sewing without any issues, you can then rethread your machine and start sewing once again.

Can I take my machine to you to be fixed or assessed?

If you are worried about your sewing machine or overlocker or have any issues, please come in to see us. Our factory trained technicians has years of experience and will do everything possible to have your machine up and running again.

What should I do if our insurance company wants a report on my sewing machine (or overlocker)?

Bring your sewing machine into us and our sewing machine technicians will review your machine and fill out the appropriate reports required by insurance companies. Whether your machine requires fixing or is a write-off we will do everything in our power to have you sewing.

Come in and see our Sewing Machine Technicans

Whether your machine is not stitching correctly, making a noise, or is just in need of a good oiling and some TLC, the Authorised Janome Repair Centre team has you covered. Our knowledgeable Janome Repair Centre technicians are fully qualified on every domestic and industrial sewing machine and overlocker brands on the market. With over 60 years of technical experience, we have learnt that there is no sewing machine problem that cannot be fixed. Whether you are looking to have your timing and tension set, or a full overhaul of your machine, you can be sure that your machine is in good hands with us.